Sehlahisoa

Dreg Organic Fertilizer Production Line

LITLHAKISO TSE HLAHANG

Kenyelletso ea sehlahisoa

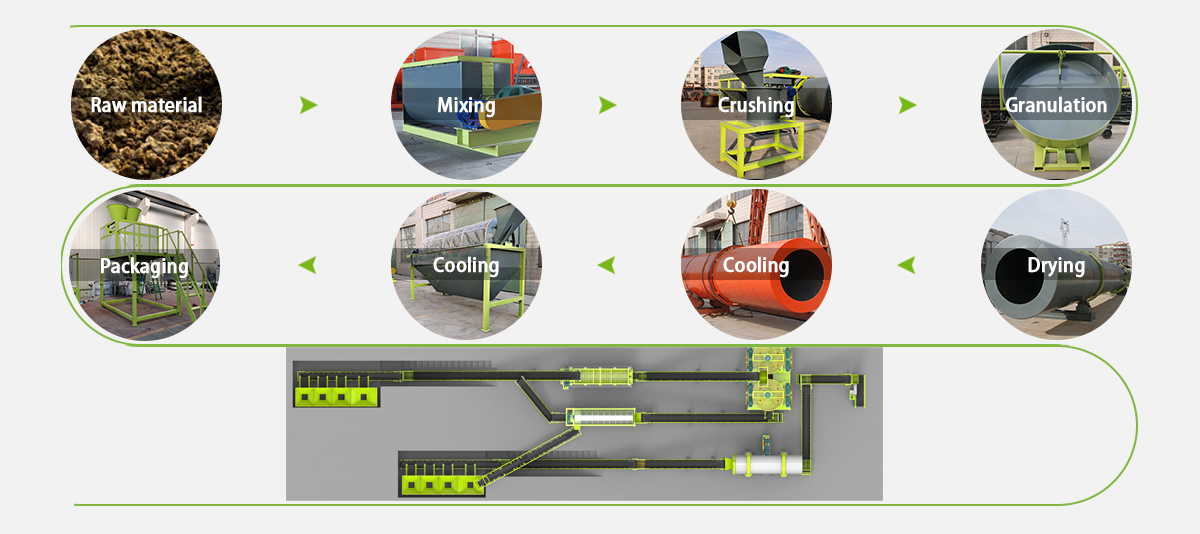

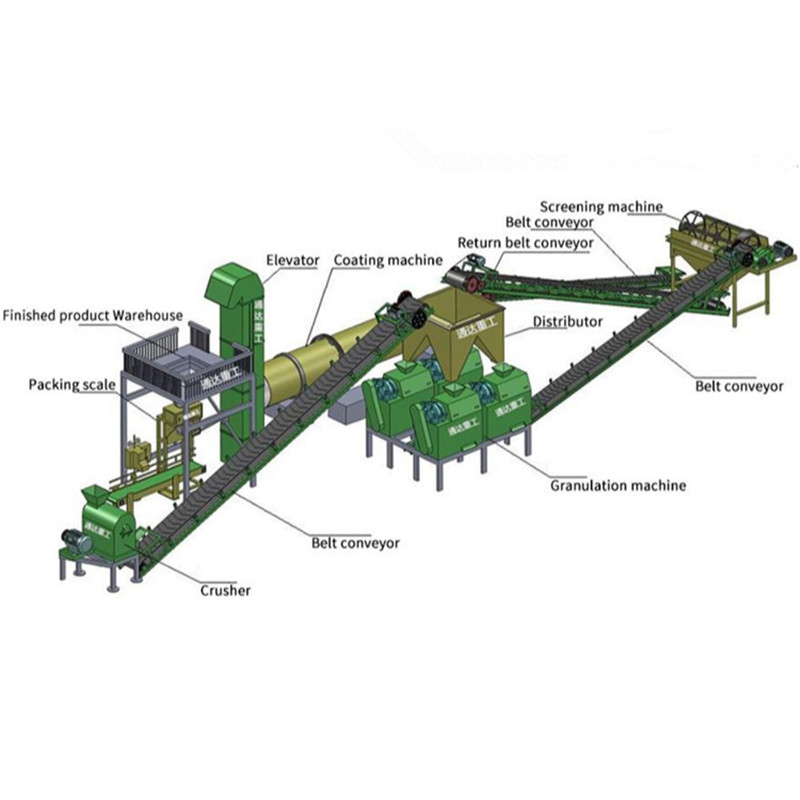

Ts'ebetso ea mahlale ea mohala oa tlhahiso ea manyolo a manyolo ka li-dregs ka kakaretso e ka aroloa ka motsoako oa lihlahisoa tse tala, motsoako oa lihlahisoa tse tala, granulation ea lihlahisoa tse tala, ho omisa granular, pholiso ea granular, granular grading, ho roala sehlahisoa se felileng le ho paka sehlahisoa sa ho qetela.

Litšobotsi tsa ts'ebetso

- Mohala oa tlhahiso ea manyolo a litšila o na le melemo ea matsete a fokolang, phello e potlakileng le molemo o motle oa moruo.

- Sebopeho se felletseng sa ts'ebetso ea lisebelisoa se kopane, sa saense ebile sea utloahala, theknoloji e tsoetseng pele.

- Ho boloka matla, ha ho na litšila, ts'ebetso e tsitsitseng, ts'ebetso e tšepahalang le tlhokomelo e bonolo.

- Ho ikamahanya le maemo ha lintho ho pharaletseng.E loketse granulation ea motsoako oa manyolo, meriana, indasteri ea lik'hemik'hale, fepa le lisebelisoa tse ling tse tala.

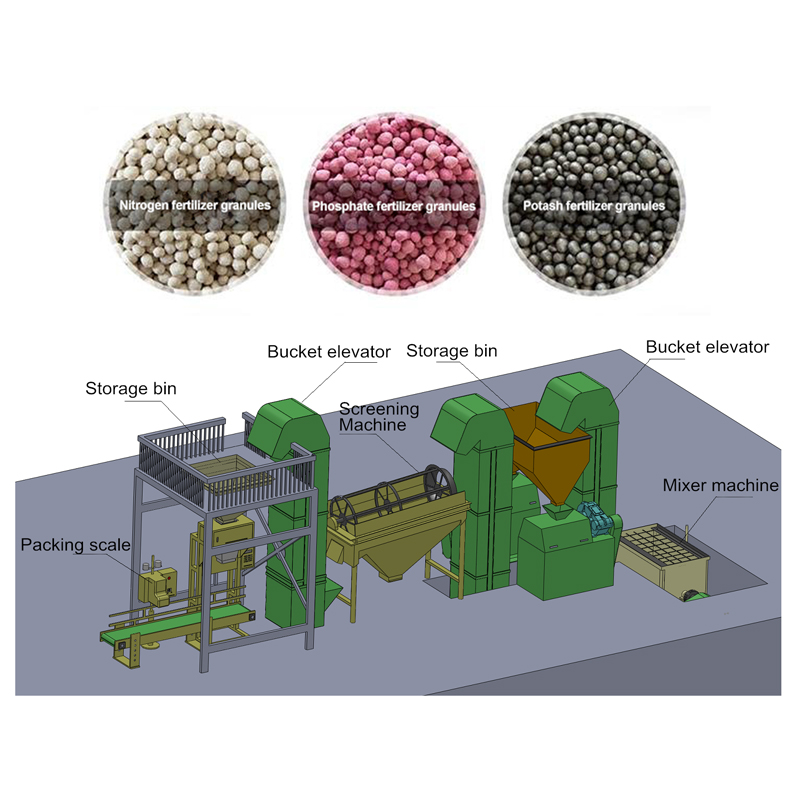

- Sehlahisoa se na le sekhahla se phahameng sa granulation.E ka hlahisa mefuta e sa tšoaneng ea menontsha e kopantsoeng, ho akarelletsa le menontsha ea tlhaho, menontsha e sa tloaelehang, menontsha ea likokoana-hloko, menontsha ea makenete joalo-joalo.

Molao-motheo oa ho sebetsa

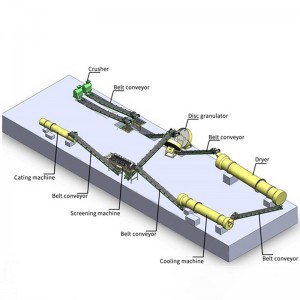

Phallo ea Mola oa Tlhahiso ea Mesaletsa ea Manyolo a Metsoako:

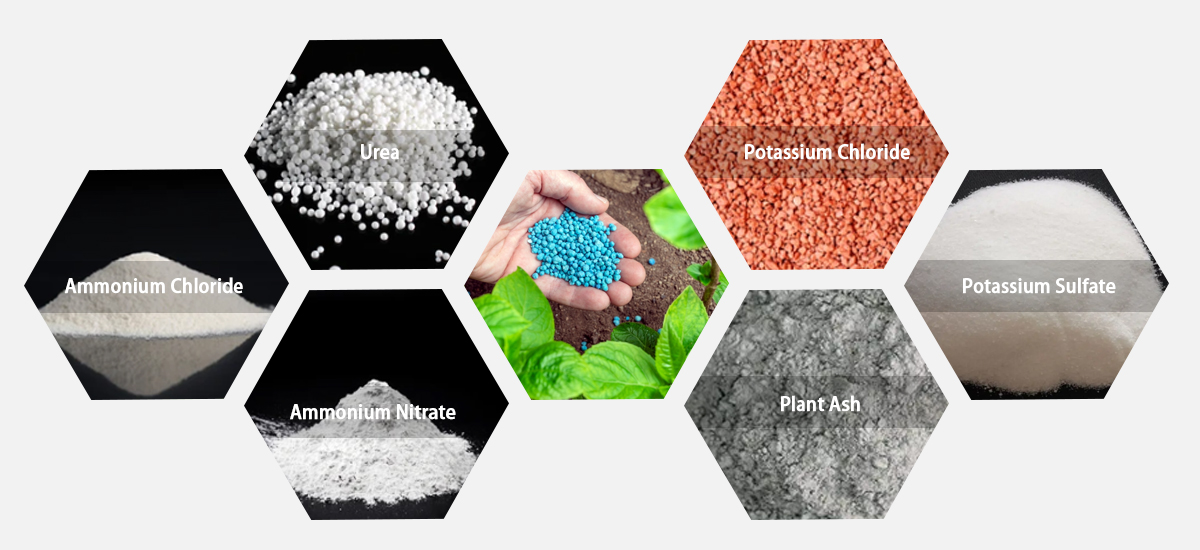

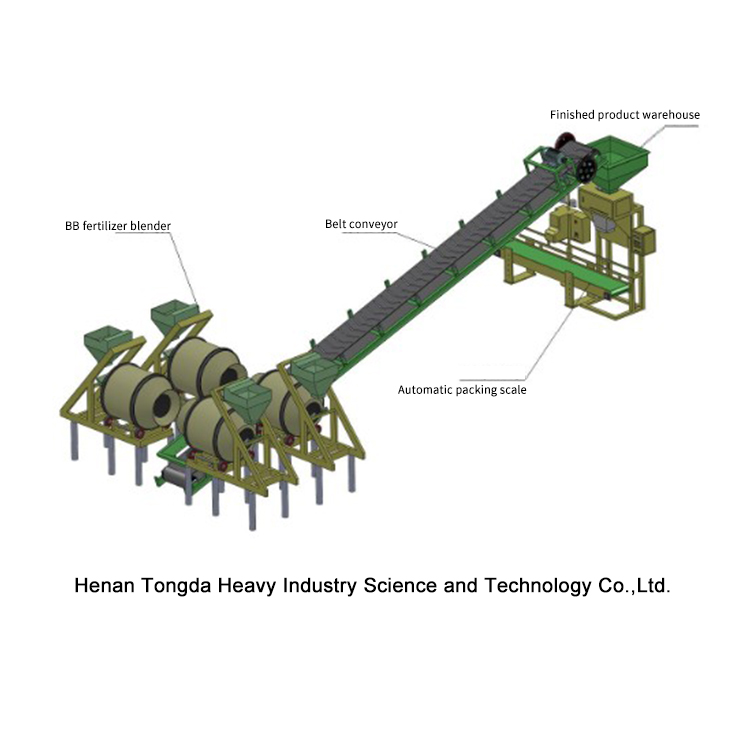

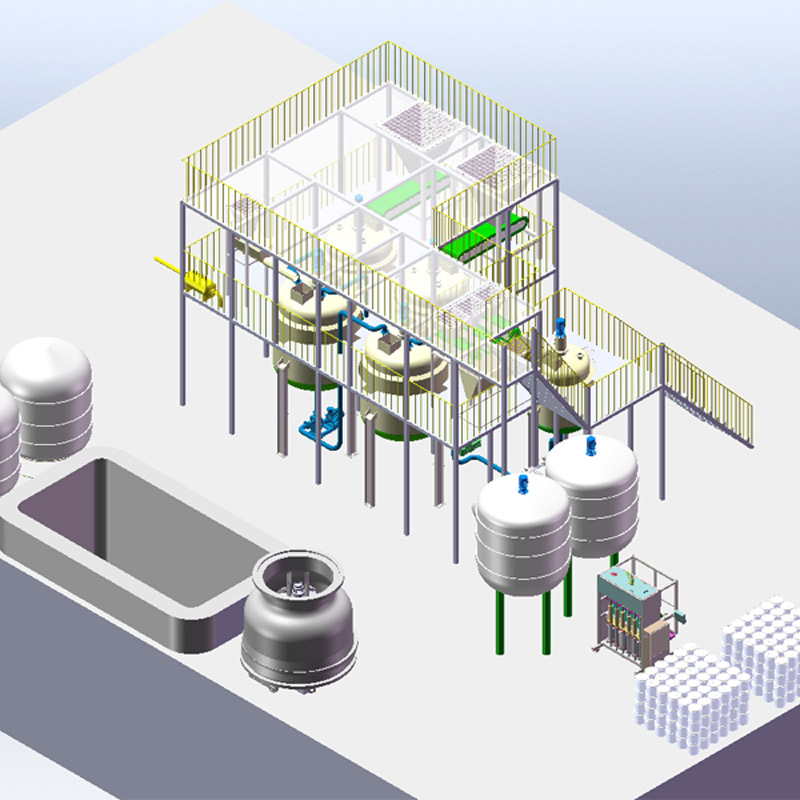

- Metsoako ea lihlahisoa tse tala: urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, k'halsiamo boima, kakaretso calcium), potasiamo chloride (potassium sulfate) le lisebelisoa tse ling tse tala li hlomelloa ka tekanyo e itseng (ho latela ho tlisa tlhokeho ya mmaraka le diphetho tsa teko ya mobu dibakeng tse fapaneng).

- Ho kopanya lintho tse bonahalang: ho kopanya lisebelisoa tse tala ka ho lekana ho ntlafatsa ts'ebetso ea manyolo e tšoanang ea granule eohle ea manyolo.

- Material granulation: Fepa lintho tse hlohlellelitsoeng ka mokhoa o ts'oanang ka har'a granulator bakeng sa granulation (moropa granulator kapa extrusion granulator e ka sebelisoa).

- Ho omisa likaroloana: Granulator e fepeloa ka har'a se omisang, 'me mongobo o ka har'a granule oa omisoa ho eketsa matla a granule le ho thusa ho e boloka.

- Pholiso ea likaroloana: Ka mor'a ho omisa, mocheso oa likaroloana tsa manyolo o phahame haholo 'me ho bonolo ho o kopanya.Ka mor'a ho pholile, ho bonolo ho boloka le ho tsamaisa ka mekotla.

- Karolo ea Karolo: Kamora ho pholile, likaroloana li aroloa.Likaroloana tse sa tšoaneleheng li pshatlehile 'me li tsosolosoa hape,' me lihlahisoa tse tšoanelehang li hlahlojoa.

- 7. Filimi e phethiloeng: apara lihlahisoa tse tšoanelehang ho eketsa khanya le ho pota-pota ha likaroloana.

- 8. Ho paka lihlahisoa tse felileng: Likaroloana tse koahetsoeng ka filimi, ke hore lihlahisoa tse felileng, lia pakoa ebe li bolokoa sebakeng se nang le moea.