Sehlahisoa

Mohala oa Tlhahiso ea Fertilizer ea Organic

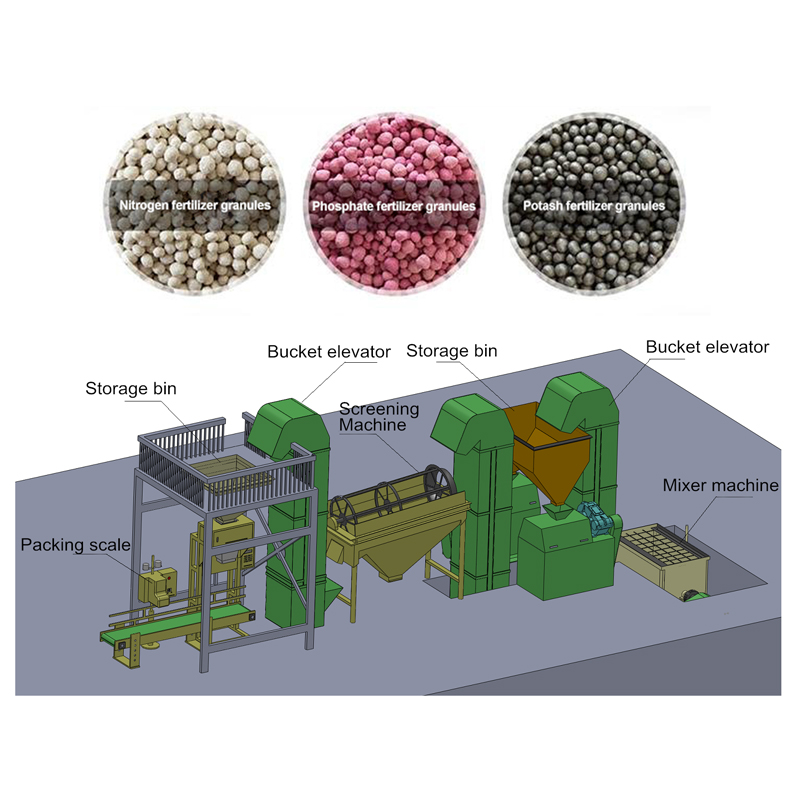

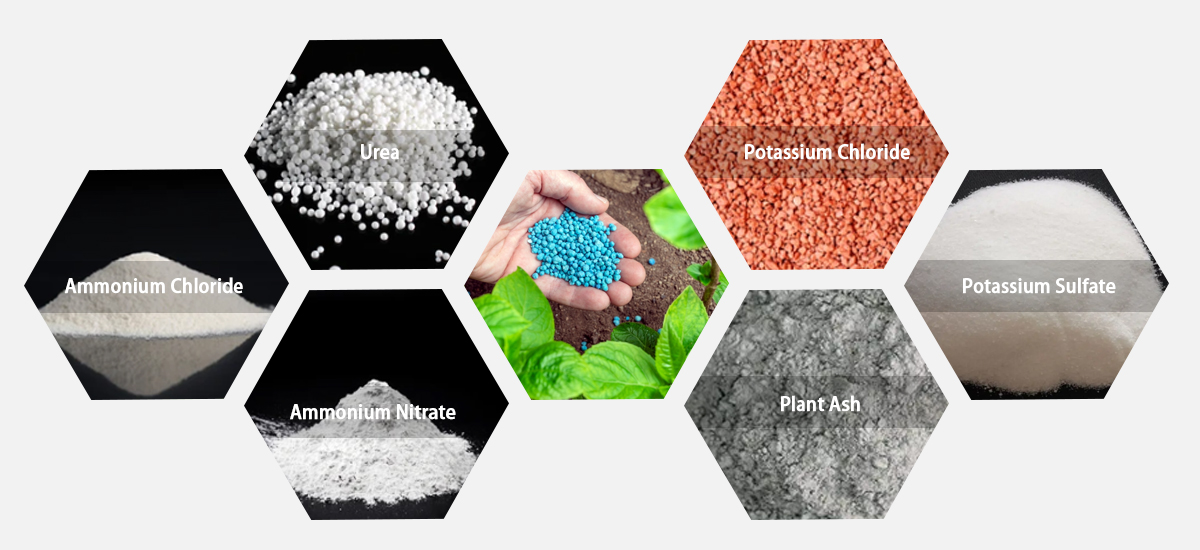

LITLHAKISO TSE HLAHANG

Semela sa tlhahiso ea manyolo ka tlhaho se sebelisoa hangata ho sebetsana le lintho tse fapaneng tse lomositsoeng ka har'a manyolo.Moiteli oa liphoofolo le litšila tsa temo li sebelisoa hape e le tsona lintho tse ka sehloohong tse tala, nts'etsopele ea mohala oa tlhahiso ea manyolo a manyolo le mokhoa oa ho thibela likokoana-hloko ka ho sebelisa moiteli oa liphoofolo le likhoho.E tla khothaletsa nts'etsopele ea temo ea tikoloho le moruo oa selikalikoe ka nepo.

Lintho tse tala tsa semela sa tlhahiso ea manyolo a manyolo:

1. Litšila tsa temo: Lehlaka, litšifa tsa linaoa, litšifa tsa k’hothone, lehlaka la raese, joalo-joalo.

2. Manyolo a liphoofolo: Motsoako oa matlakala a likhoho le litšila tsa liphoofolo, joalo ka litšila tsa mahlabelo, 'maraka oa litlhapi, moroto le bolokoe ba likhomo;

Likolobe, linku, likhoho, matata, likhantsi, poli, joalo-joalo.

3. Litšila tsa indasteri: Litlhapi tsa veine, masala a asene, litšila tsa manioc, tsoekere ea tsoekere, masala a boea, joalo-joalo.

4. Lithako tsa lapeng: Litšila tsa lijo, metso le makhasi a meroho, joalo-joalo.

5. Sludge: Leretse la noka, likhoerekhoere, joalo-joalo.

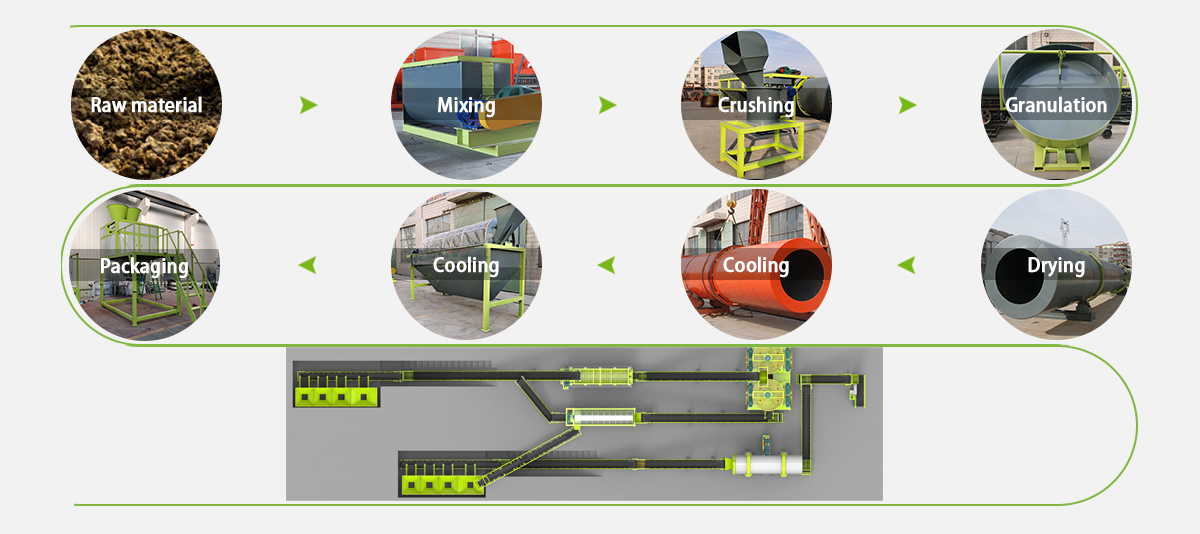

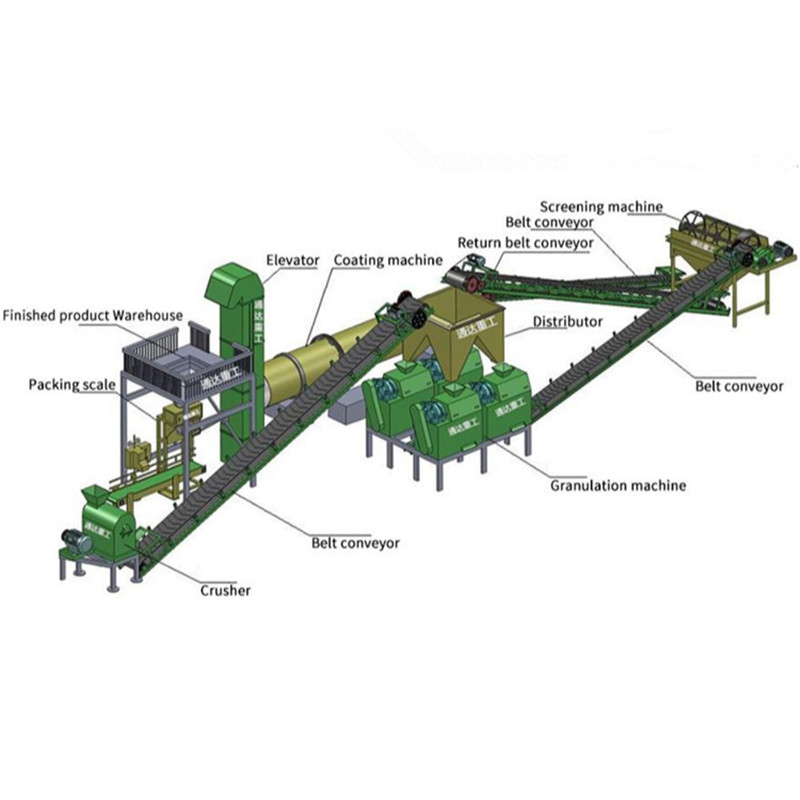

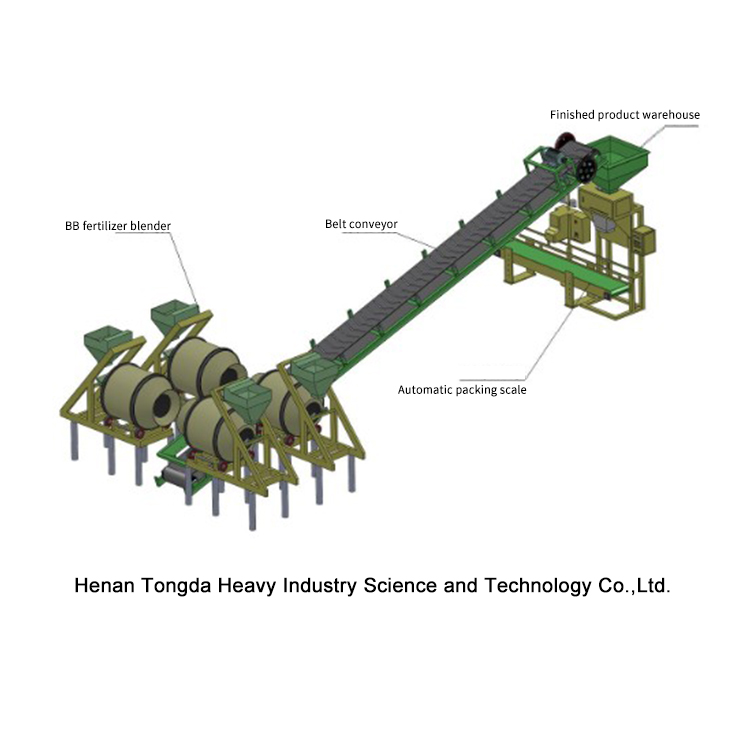

Mochine oohle oa tlhahiso ea manyolo ka litlama o kenyelletsa mechini e latelang: ho belisoa → mochini o silakanyang manyolo → mochini o kopanyang manyolo → moqomo oa manyolo o potolohang → mochini o pholileng oa manyolo → mochini oa ho roala moqomo oa manyolo → mochini oa ho hlahloba manyolo → conveyor lebanta → le lisebelisoa tse ling.

1. Ts'ebetso ea ho belisoa ha lintho tsa tlhaho e phetha karolo ea pele empa e le ea bohlokoa molemong oa tlhahiso ea manyolo.Mefuta e 'meli ea mantlha ea manyolo ka litlama e sebelisoa haholo ho fetola le ho kopanya manyolo le ho potlakisa lebelo la ho belisoa: Moiteli o itšebetsang oa manyolo le hydraulic compost turner.

2. Ts'ebetso ea ho sila: Lisebelisoa tsa manyolo ka litlama li lokela ho siloa pele ho ts'ebetso ea granulating.Empa re ka tlohela ts'ebetso ea ho senya ha manyolo a manyolo a lekana hantle.Vertical chain crusher le double-shaft horizontal crusher, mefuta e 'meli ea mochini o silang e ka sebelisoa ho pshatla lisebelisoa tse tala tsa manyolo a manyolo.

3.Tsamaiso ea ho kopanya, mefuta e 'meli ea mochine oa ho kopanya e sebelisoa ho kopanya lisebelisoa tse tala moleng oa tlhahiso ea manyolo: Motsoako o otlolohileng le o otlolohileng.

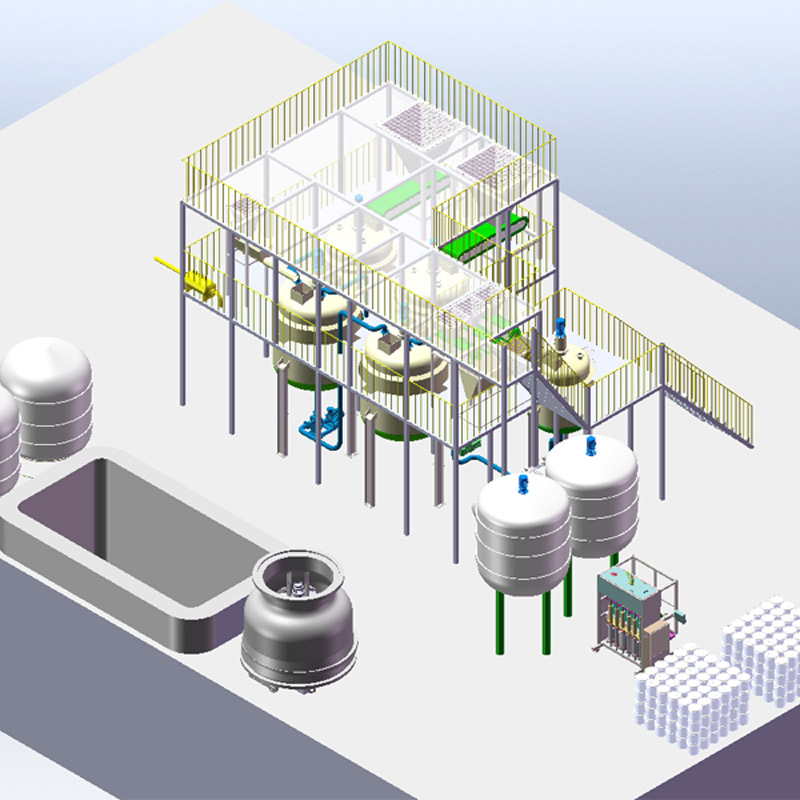

4.Drying tshebetso.Ha manyolo a granulating, mongobo oa lisebelisoa tse tala tsa manyolo o lokela ho ba tlase ho 25%, kahoo re lokela ho omisa lisebelisoa tse tala haeba mongobo o feta 25%.Mochini oa ho omisa meropa oa rotary o sebelisoa haholo ho omisa manyolo ka tekanyo e itseng ea mongobo le boholo ba likaroloana.

5.Ts'ebetso ea granulator ea manyolo.Granulating process ke karolo ea mantlha moleng ona oa tlhahiso, kahoo re khetha mohlala o loketseng oa granulator ea manyolo ho latela litlhoko tse qaqileng tsa bareki.Thepa ea boikhethelo ea granulator: granulator ea manyolo a manyolo, granulator e khethehileng ea manyolo, para roll extrusion granulator, disc granulator, filimi e bataletseng. granulator, bio organic fertilizer spherical granulator, drum granulator, mochini o tsokotsang, joalo-joalo;lisebelisoa tse tloaelehileng tsa ts'ebeliso: manyolo a likhoho, bolokoe ba khomo, kaolin, joalo-joalo.

6.Rotary drum cooling machine e sebelisetsoa manyolo a pholileng ho etsa hore likaroloana tsa manyolo li be matla.

7.Screening process: Mochini oa ho hlahloba drum oa rotary o sebelisetsoa ho arola li-granules ho tloha likarolong tse kholo tse lokelang ho khutlisetsoa bakeng sa ho senya le ho senya ka lekhetlo la bobeli.Mochini oa ho roala moqomo oa Rotary o sebelisetsoa ho koahela manyolo le ho thibela manyolo ho khomarela.

8.Ts'ebetso ea ho qetela ke mokhoa oa ho paka.Mochini oa ho paka manyolo o ka paka mekotla ka bongata le ka bo eona. Ho kenyeletsoa le sekala sa packaging sa elektroniki. E boetse e hloka lisebelisoa tse ling tse thusang bakeng sa ho hokela joalo ka sehatsetsi sa mabanta, lifti ea libakete, jj.

Sebetsa se phahameng sa tlhahiso:

All process is automatic operation.Ts'ebetso e bonolo, ke batho ba babeli feela ba ka sebetsang.

Theko e tlase ea ts'ebetso le tšebeliso e tlase ea matla:

Mefuta eohle ea manyolo a liphoofolo a ka sebetsoa.4 lihora tse baeloji dedorization.Ts'ireletseho ea matla a ho khutlisa mocheso le ts'ireletso ea tikoloho.E loketse mapolasi a maholo, a mahareng le a manyane.

E sebelisoa haholo ka lihlahisoa tse feliloeng:

Ho hlahisa polasi ea likolobe, polasi ea likhomo, joalo-joalo. Ho sebelisoa ha mochini oa mofuta ona oa ho etsa manyolo ka litlama ho na le bohlokoa bo botle haholo bakeng sa ts'ireletso ea tikoloho.