Sehlahisoa

Dreg Organic Fertilizer Production Line

LITLHAKISO TSE HLAHANG

Kenyelletso ea sehlahisoa

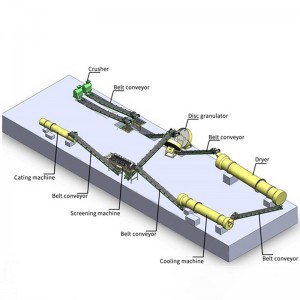

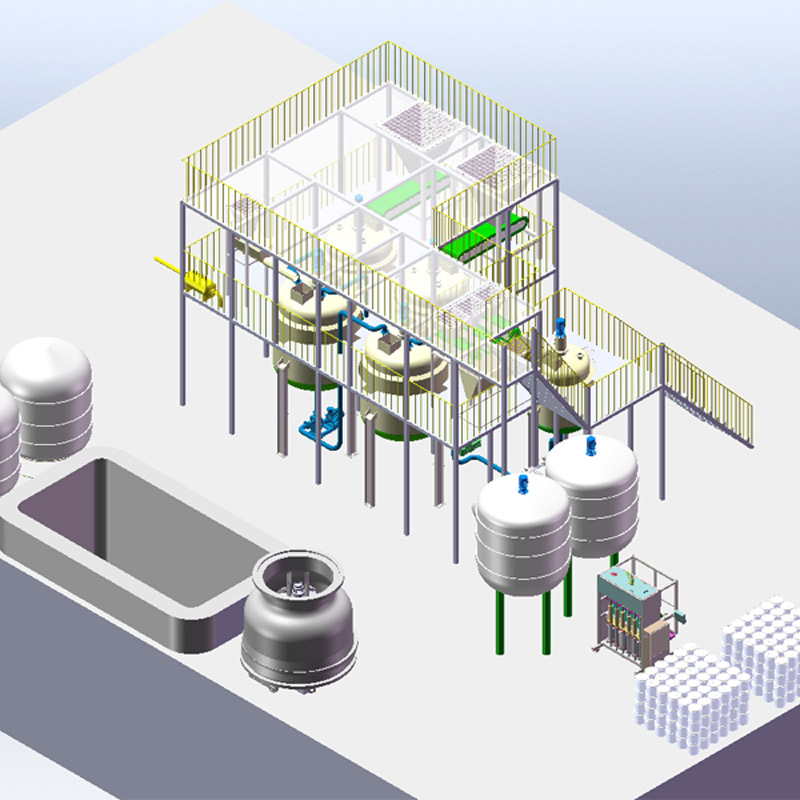

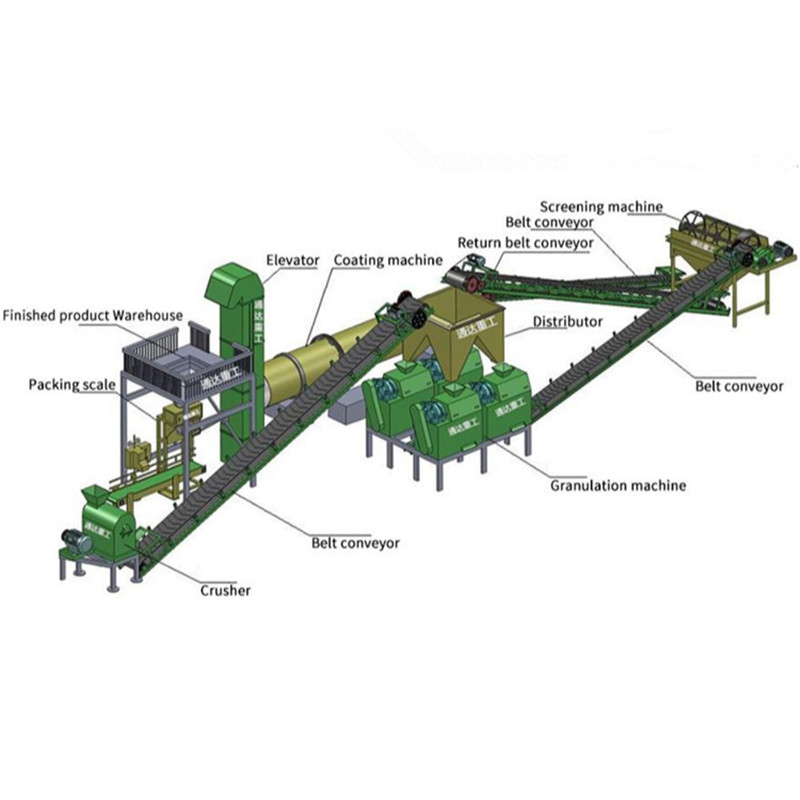

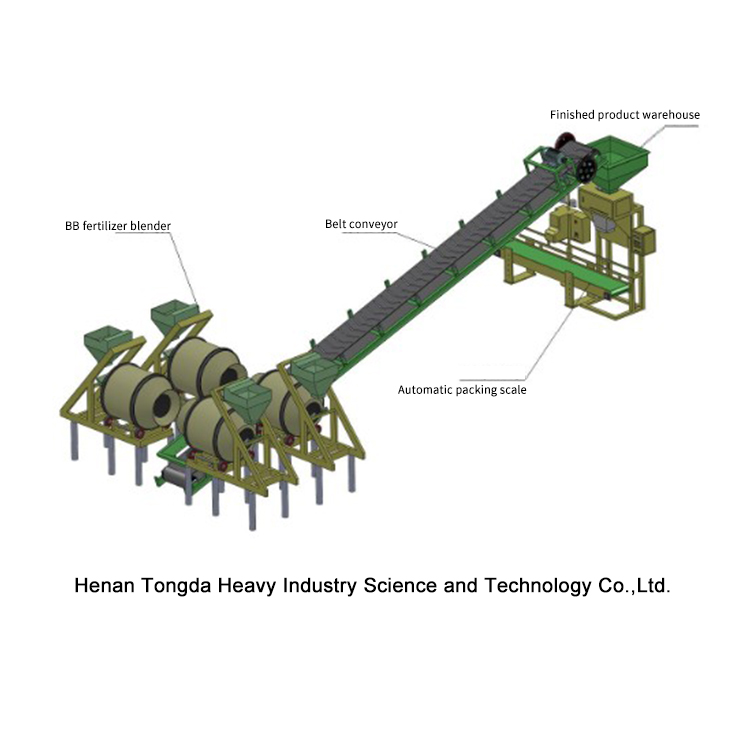

Ts'ebetso ea mahlale ea mohala oa tlhahiso ea manyolo a manyolo ka li-dregs ka kakaretso e ka aroloa ka motsoako oa lihlahisoa tse tala, motsoako oa lihlahisoa tse tala, granulation ea thepa e tala, ho omisa granular, pholiso ea granular, granular grading, koae ea sehlahisoa se felileng le ho paka sehlahisoa sa ho qetela.

Litšobotsi tsa ts'ebetso

- Mohala oa tlhahiso ea manyolo a litšila o na le melemo ea matsete a fokolang, phello e potlakileng le molemo o motle oa moruo.

- Sebopeho se felletseng sa ts'ebetso ea lisebelisoa se kopane, sa saense ebile sea utloahala, theknoloji e tsoetseng pele.

- Ho boloka matla, ha ho na litšila, ts'ebetso e tsitsitseng, ts'ebetso e tšepahalang le tlhokomelo e bonolo.

- Ho ikamahanya le maemo ha lintho ho pharaletseng.E loketse granulation ea motsoako oa manyolo, meriana, indasteri ea lik'hemik'hale, fepa le lisebelisoa tse ling tse tala.

- Sehlahisoa se na le sekhahla se phahameng sa granulation.E ka hlahisa mefuta e sa tšoaneng ea menontsha e kopantsoeng, ho akarelletsa le menontsha ea tlhaho, menontsha e sa tloaelehang, menontsha ea likokoana-hloko, menontsha ea makenete joalo-joalo.

Molao-motheo oa ho sebetsa

Phallo ea Mola oa Tlhahiso ea Masala a Fertilizer:

- Metsoako ea lihlahisoa tse tala: urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, k'halsiamo boima, kakaretso calcium), potasiamo chloride (potassium sulfate) le lisebelisoa tse ling tse tala li hlomelloa ka tekanyo e itseng (ho latela ho tlisa tlhokeho ya mmaraka le diphetho tsa teko ya mobu dibakeng tse fapaneng).

- Ho kopanya lintho tse bonahalang: ho kopanya lisebelisoa tse tala ka ho lekana ho ntlafatsa ts'ebetso ea manyolo e tšoanang ea granule eohle ea manyolo.

- Material granulation: Fepa lintho tse hlohlellelitsoeng ka mokhoa o ts'oanang ka har'a granulator bakeng sa granulation (moropa granulator kapa extrusion granulator e ka sebelisoa).

- Ho omisa likaroloana: Granulator e fepeloa ka har'a se omisang, 'me mongobo o ka har'a granule oa omisoa ho eketsa matla a granule le ho thusa ho e boloka.

- Pholiso ea likaroloana: Ka mor'a ho omisa, mocheso oa likaroloana tsa manyolo o phahame haholo 'me ho bonolo ho o kopanya.Ka mor'a ho pholile, ho bonolo ho boloka le ho tsamaisa ka mekotla.

- Karolo ea Karolo: Kamora ho pholile, likaroloana li aroloa.Likaroloana tse sa tšoaneleheng li pshatlehile 'me li tsosolosoa hape,' me lihlahisoa tse tšoanelehang li hlahlojoa.

- 7. Filimi e phethiloeng: apara lihlahisoa tse tšoanelehang ho eketsa khanya le ho pota-pota ha likaroloana.

- 8. Ho paka lihlahisoa tse felileng: Likaroloana tse koahetsoeng ka filimi, ke hore lihlahisoa tse felileng, lia pakoa ebe li bolokoa sebakeng se nang le moea.